Welcome to our science page

where we explain the key scientific improvements that will change the way we use hydroponics in the future.

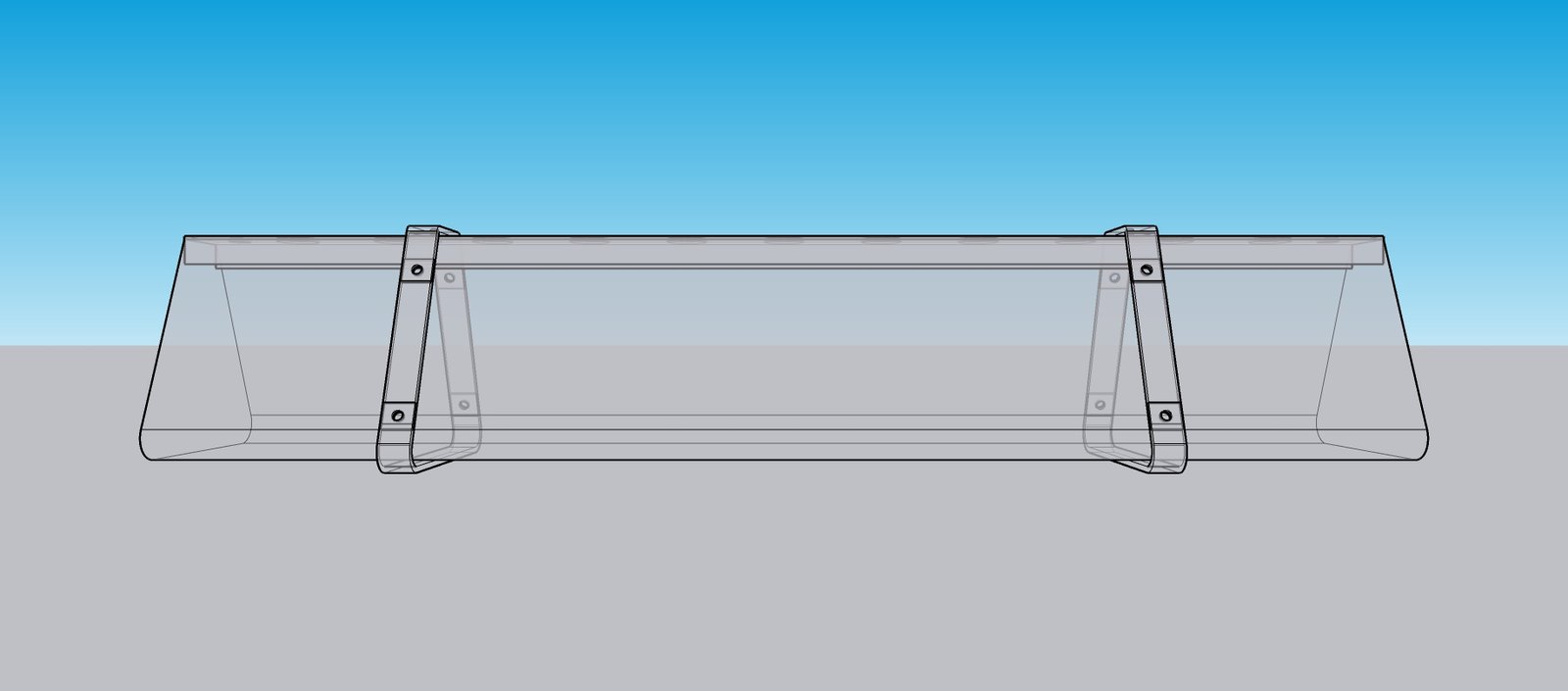

PHOTO “SP 1” in the cloud

Hydroponics, the soil-less cultivation of plants, has long been a promising alternative to traditional soil-based agriculture. It allows for precise control over nutrient delivery, water usage, and environmental conditions, resulting in increased crop yields and resource efficiency. Traditionally, hydroponic systems have relied on external reservoirs to supply plants with water and nutrients. However, our groundbreaking innovation has emerged, eliminating the need for these external reservoirs and revolutionizing the way we approach soil-less cultivation.

The conventional hydroponic systems typically involve a central reservoir that stores nutrient-rich water. This water is then pumped through a network of tubes or channels to reach individual plants. While effective, this setup has its limitations. The need for a centralized reservoir can lead to challenges in cleaning and using extra energy pumping the water around, Additionally, it requires substantial space and resources, making it less sustainable in certain settings.

The newly invented hydroponic system overcomes these limitations by integrating a self-contained mechanism within each plant module. This groundbreaking approach has far-reaching implications for the efficiency, flexibility, and sustainability of hydroponic agriculture.

At the heart of this innovation lies a complete reworking of traditional components, instead of PVC gutters which have been hijacked from other industries, we use frames and purpose designed tables, allowing easy access to the plants and greater yields.

Photo “SP 2” as in the cloud

In the future our original design will become a closed-loop feedback system. Each plant module will be equipped with sensors that continuously monitor key parameters such as nutrient levels, pH, and moisture content in the root zone. These sensors communicate with an intelligent control unit, which dynamically adjusts nutrient and water delivery based on real-time data. This closed-loop feedback system ensures that each plant receives precisely what it needs, optimizing growth and resource utilization.

One of the key advantages of this flexible reservoir hydroponic system is its scalability and adaptability. Traditional hydroponic systems face challenges when scaling up or down due to the centralized nature of their reservoirs. In contrast, the new system allows for modular expansion, making it suitable for a wide range of applications, from small-scale urban farming to large commercial operations. This scalability enhances its accessibility and usability, opening doors for hydroponic farming in diverse environments. Scalability will be introduced into our systems on commercial models.

Furthermore, the elimination of external reservoirs reduces the risk of contamination and disease spread. Centralized reservoirs can become breeding grounds for pathogens and algae, posing a threat to the entire crop. The self-contained nature of the new hydroponic system minimizes these risks, creating a more resilient and biosecure environment for plant growth.

The introduction of replaceable bladders in the new hydroponic system marks a significant departure from traditional methods, presenting a streamlined and efficient solution to several challenges inherent in soil-less cultivation. Unlike conventional systems that often require extensive cleaning with chemicals and disassembly of complex structures, the replaceable bladder design offers a more user-friendly and sustainable approach.

Traditionally, hydroponic systems demand meticulous cleaning routines to prevent the buildup of algae, pathogens, and other contaminants that can compromise plant health. The replaceable bladder system eliminates the need for arduous cleaning procedures. When a bladder reaches the end of its use or encounters any issues, it can be swiftly replaced within minutes. This not only reduces downtime but also enhances overall system hygiene.

The quick replacement of bladders simplifies maintenance, making it accessible to a wider range of users, including those without specialized agricultural expertise. This user-friendly feature encourages broader adoption of hydroponic farming, from hobbyists to commercial growers, fostering a more inclusive and participatory agricultural landscape.

Furthermore, the bladder design contributes to resource efficiency. Traditional hydroponic systems may require the disposal of nutrient solutions during cleaning, leading to unnecessary wastage. The replaceable bladder system allows for targeted maintenance without disturbing the entire nutrient reservoir, minimizing nutrient loss and promoting a more sustainable use of resources.

Photo “SP 3” as in the cloud

From a logistical standpoint, the simplicity of bladder replacement streamlines operational procedures. This efficiency is valuable to homes users and large-scale commercial hydroponic farms where time is of the essence. Growers can focus on maximizing productivity and crop yields without the logistical challenges associated with disassembling and cleaning entire systems. Home users can focus on researching recipes for their nutritious new herbs.

In essence, the innovation of replaceable bladders in the new hydroponic system not only simplifies maintenance but also democratizes hydroponic farming. By minimizing the barriers to entry and promoting resource-efficient practices, this design is poised to redefine how we approach soil-less cultivation, making hydroponics more accessible, efficient, and sustainable for a diverse range of users.

Traditionally, hydroponic systems are characterized by a fixed structure, making adjustments for expansion or reduction in size a cumbersome task. In contrast, the modular design allows each hydroponic unit to connect seamlessly with others, creating a scalable framework. This scalability is essential for adapting to varying spatial constraints, making it suitable for diverse settings ranging from small urban spaces to expansive commercial farms.

The modular system enhances operational efficiency by facilitating targeted adjustments. Growers can easily add or remove modules based on their specific needs, optimizing resource usage and reducing waste. This adaptability ensures that the hydroponic system remains in harmony with the scale of cultivation, promoting a more sustainable and cost-effective approach to farming.

Furthermore, the ability to connect modules fosters a more integrated and cohesive system. Each module can share resources such as nutrient solutions, reducing the need for redundant infrastructure and streamlining the overall setup. This interconnectedness enhances the distribution of resources, ensuring a more uniform and controlled environment for plant growth.

The scalability of the modular hydroponic system not only caters to different spatial requirements but also accommodates varying levels of expertise. Whether it’s a novice experimenting with a small setup or a seasoned farmer expanding operations, the modular design makes hydroponic farming accessible to a broad spectrum of users.

In conclusion, the modular nature of the new hydroponic system represents a paradigm shift in the scalability and adaptability of soil-less cultivation. By allowing seamless connectivity between modules, this design offers a dynamic and efficient solution that can be tailored to meet the evolving needs of growers, ultimately contributing to a more responsive, scalable, and user-friendly approach to hydroponic agriculture.